CNC MACHINE SHOP DENVER

Great manufacturing starts with efficient process planning and quality machines. That’s why we continually update our machine shop with the newest technologies to stay at the forefront of our industry.

Our modern state-of-the-art CNC mills will exceed your manufacturing expectations. We regularly calibrate our mills and maintain stringent factory specifications. This means our mills can handle high-production quotas and very tight tolerances.

CNC Machining Services

At Metalcraft, the only metalworking firm in Colorado that offers CNC machining services, precision sheet metal fabrication, metal stamping, contract manufacturing, and a vast array of post-production services all under one roof, we have enjoyed working with small, medium-sized, and large businesses over the past three-quarters of a century.

While many customers are well-versed in our industry’s products, services, and terminologies, others are relative neophytes who are still gaining knowledge. Accordingly, let’s fully analyze CNC (computer numerical control) machining and discuss how the process, and our services, can boost your bottom line.

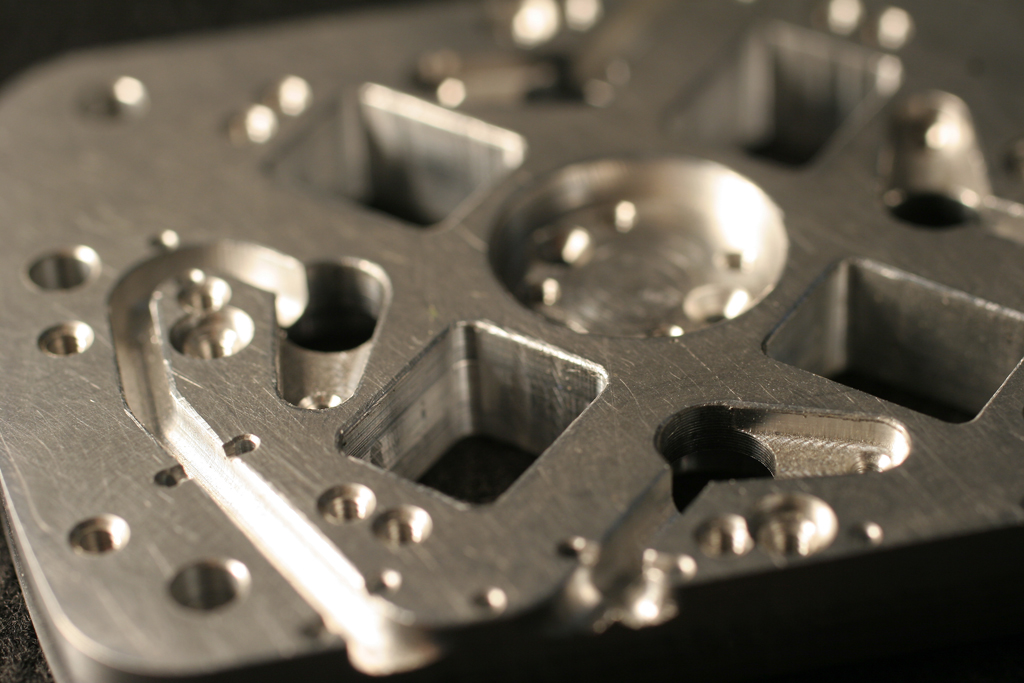

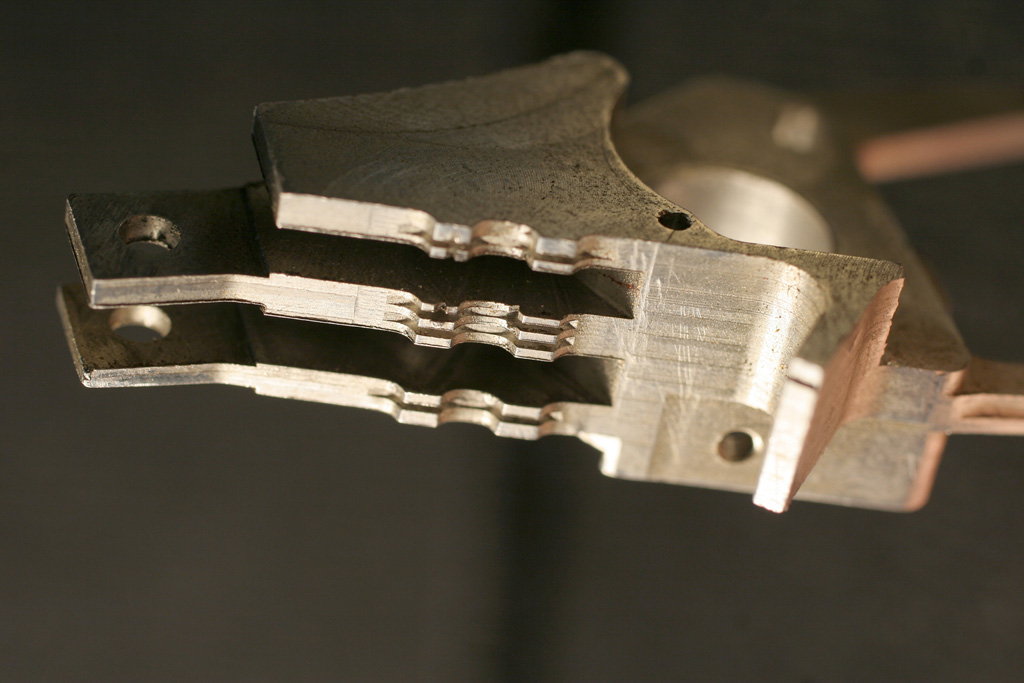

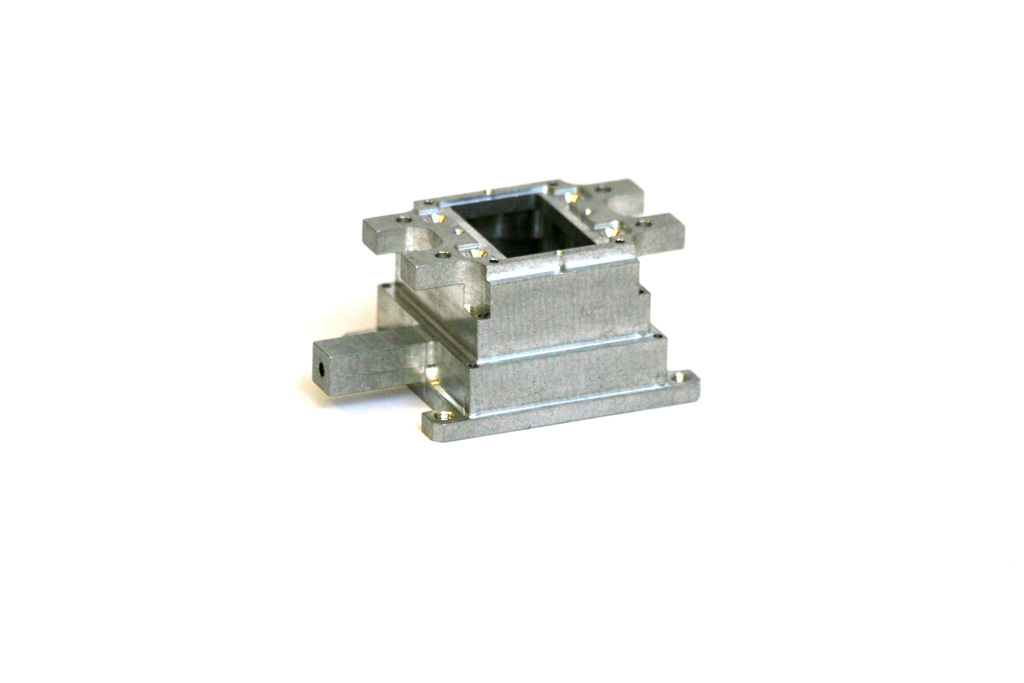

CNC Machined Parts

An overview of CNC machining

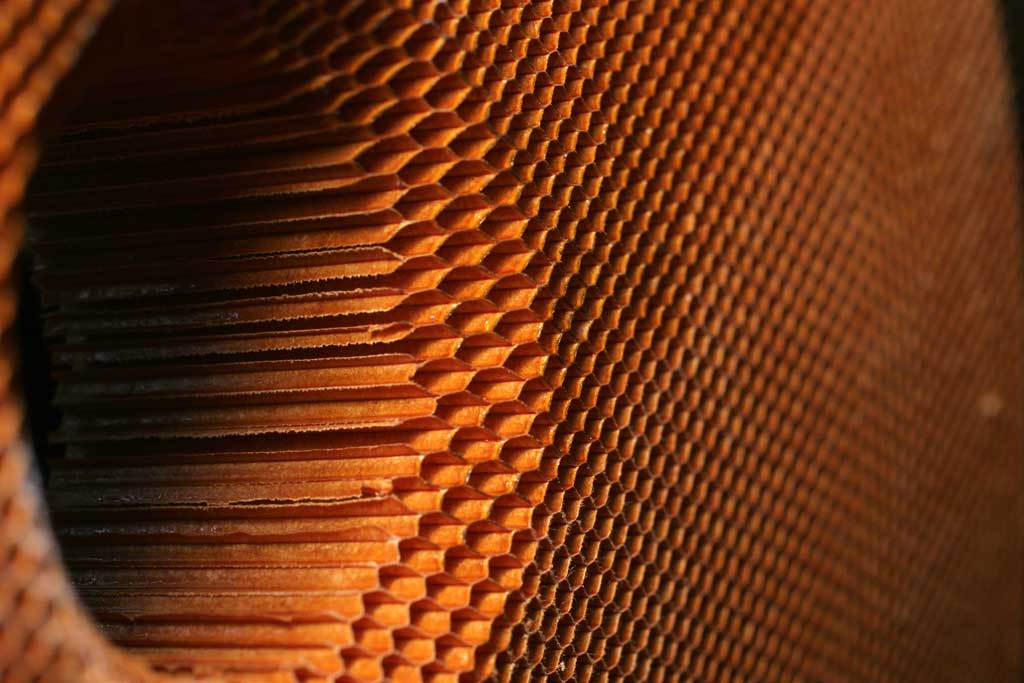

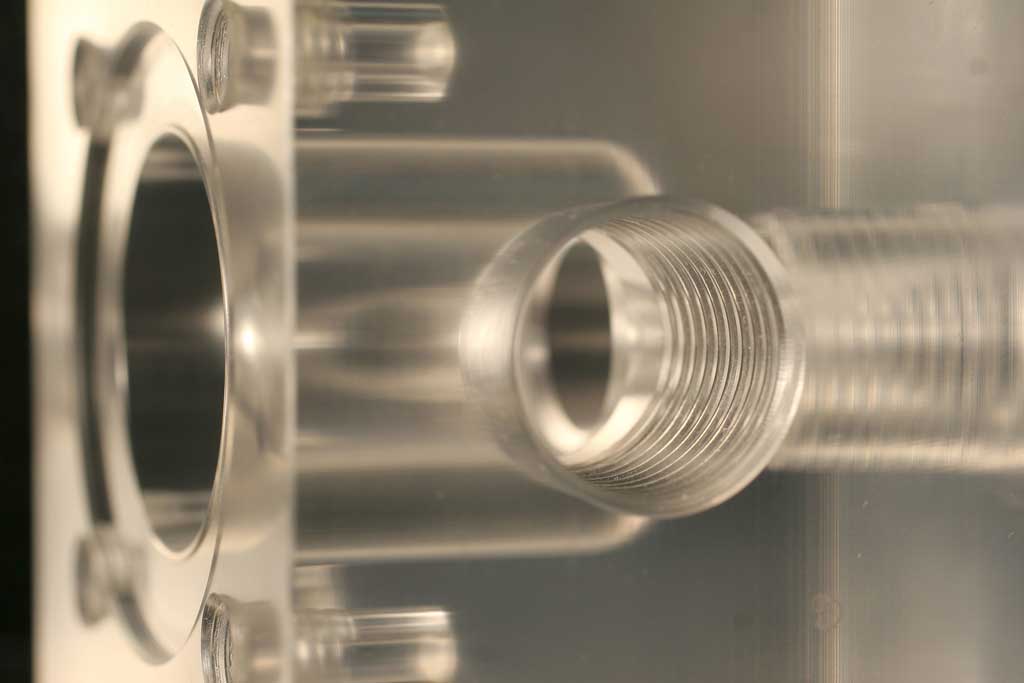

CNC machining is a subtractive manufacturing process that employs pre-programmed computer software to control the movements of machine tools and machinery. This process is more efficient and cost-effective than manual operations. A CNC machine can create a part out of solid stock materials, such as plastics, metals, aluminum, wood, and more to meet specifications and requirements in product development. Furthermore, equipped with software programs and consoles, it can produce three-dimensional objects in a single set of prompts. CNC machining is a favored technique that is used worldwide and for multiple industries.

Types of software utilized in CNC machining

- Computer-aided drawing (CAD) - CAD software, frequently deemed the starting point for CNC projects, allows engineers, architects, and designers to revise, examine, or hone a product to its desired shape. This software, which includes renowned programs like AutoCAD, SolidWorks, ProE, and Rhino3D, can increase output, upgrade design quality, boost effective communication, coordinate progress, and more.

- Computer-aided manufacturing (CAM) - Also called computer-aided modeling or computer-aided machining, this software helps manufacturers accelerate the process of modifying raw materials and components into their final form. CAM, which often complements CAD software and is utilized in the mechanical, electrical, industrial, and aerospace engineering industries, allows fabricators to establish tool paths, and conduct simulation runs before starting the cutting procedure.

Types of CNC machines

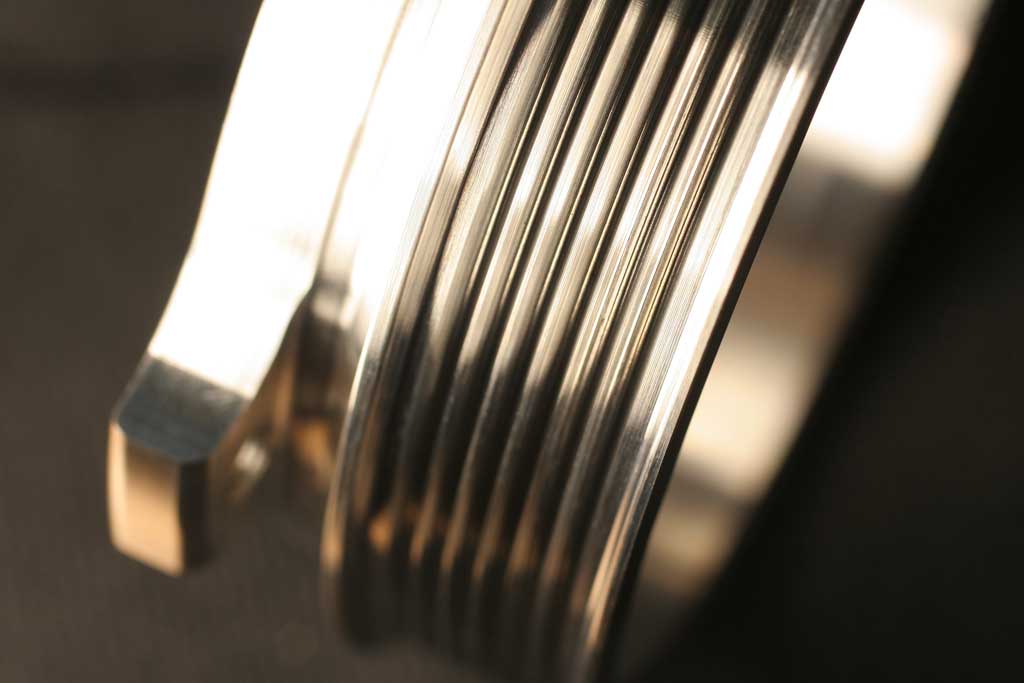

- CNC lathe, commonly called carbide tooling and frequently employed in basic machining operations like turning and drilling, can proficiently, and consistently, create symmetrical cylindrical parts.

- A router is a computer-controlled machine that makes cuts in three axes or directions. It runs at high, rotational speeds and is designed for cutting softer materials, such as wood, plastic, and foam.

- CNC mill is ideal for machining wood, metal, plastic, glass, and a slew of other materials. It uses computerized controls and rotating multipoint cutting tools to progressively remove materials from the workpiece and manufacture a made-to-order part or product.

Applications for CNC machining

CNC machines are remarkably adaptable and can be employed for an array of functions across multiple sectors. These machines are especially ideal for prototyping, production, tooling, and hybrid manufacturing.

Always remember that expert manufacturing starts with efficient process planning and quality machines. That’s why we continually update our machine shop with the newest technologies to stay at the forefront of our industry.

Our ultramodern CNC mills will exceed your manufacturing expectations. We regularly calibrate our mills and maintain stringent factory specifications. This means our mills can handle high-production quotas and very tight tolerances.

How CNC machines operate

These machines operate by moving on an axis to cut materials to their required form. Standard machining tasks can be completed with one or two axes. On the flip side, state-of-the-art CNC machines can maneuver laterally, longitudinally, and rotationally. Moreover, they are a practical option for 4-axis horizontal machining and 5-axis machining.

Click on the below links to watch how CNC machines function:

CNC machining advantages

- Dependable and flexible

- Exceptional precision ensures superior parts

- Elevated level of production and adjustable scalability

- Decreased labor

- Routinely create uniform products

- Reduced costs

- Minimal maintenance

- Maximum safety

- Cost-effective

- Fast turnaround times

- Near-zero downtime

CNC machining disadvantages

- More costly than manually operated machines

Why Choose Metalcraft

Learn with us, improve your products, reduce your price, and ease your quality concerns. You understand your product and we have seven decades of manufacturing knowledge. Together we can devise great solutions. Contact us today to start your build.