CONTRACT METAL MANUFACTURING WITH METALCRAFT INDUSTRIES

How Modern Manufacturing Has Changed

Contract manufacturers, like us, can execute entire projects, from concept to commercialization. New technologies allow us to customize and mass-produce components quickly. Designs and builds that once took years of planning and execution now take months or less.

Manufacturing Future: The Robotic Revolution

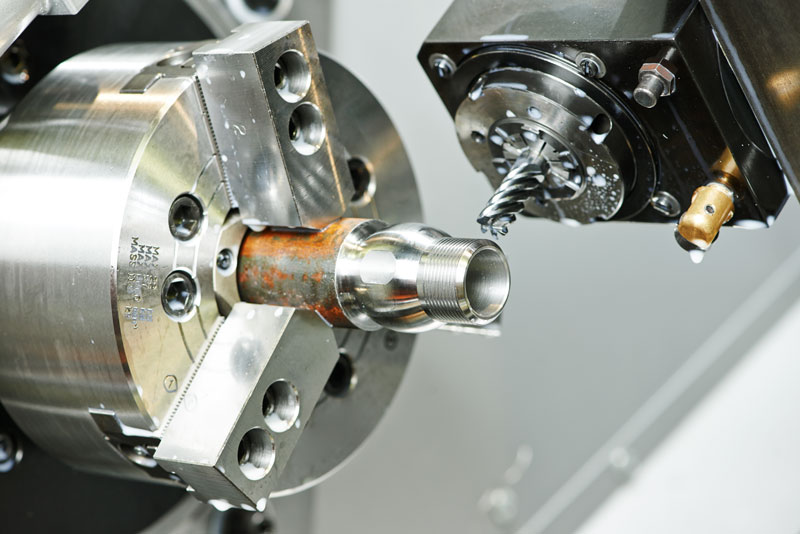

While Metalcraft’s contract metal manufacturing still has a high level of human oversight, we automated much of the heavy lifting. From robotic welding, laser cutting, and assembly, to advanced tools like interconnected factory computer systems, automation has become commonplace in innovative fabrication and machine shops. It’s one of the ways we stay modernized so we can offer competitive pricing and provide the most effective service.

Manufacturing Experts: A Necessary Human Touch

Though automation has changed the manufacturing game, it still requires decisive, meticulous, and intuitive human oversight. We pay attention to the small details while maintaining focus on the big picture of your overall design, from establishing your bill of materials to defining dimensions.

Product Life Cycle Management

Metalcraft clients look to us for Product Life Cycle Management (PLM) because of our holistic approach. PLM is the journey of an entire product, from its conception to its disposal or recycling including:

- Part drawings

- Supply chain management

- Build-out

- Packaging

- Distribution

Well-thought-out PLM merges an organization’s overarching vision with its plans for the product. It also lowers cost and time to market for new product development. Through our decades of experience, we’ve found that our well-rounded PLM services yield a preferable finished product.

Contract Metal Manufacturing Services: What We Can Do

Our technicians test and adapt as they complete each job to ensure the best outcome possible. We typically engage in four types of contract jobs:

- Box Build Assembly

- Supply Chain Management

- Electronics

- Wiring

- Controls

- Finishes

- Logistics

- Integration

- Part Drawing Consultation

- Full Build Out

Box Build Assembly

The box build process of systems integration goes beyond producing a printed circuit board. It’s an electromechanical assembly process, involving enclosure fabrication, installation, and the routing of cables or wires.

We can help you with multiple box build processes, including:

- System-Level Assembly

- General Product Assembly

- Packaging and Labeling

Whether you need a simple cabinet of wires or a complex electronic system, Metalcraft’s’ engineer-minded technicians will find the right build.

Integration

New product development requires a lot of planning before execution. We like to get involved in the beginning stages of our clients’ projects and work together toward smart solutions. When you bring us into the strategy process early on, during the “front-end” of development, we can discover and fix issues before they arise.

Full Build-Out

Fully building out a product means the contract manufacturer carries out the entire product lifecycle. The manufacturer will strategize, conceptualize, measure, engineer, develop, prototype, mass-produce a product. When you partner with us on a full build-out, you get to focus on your project’s big picture while we handle the day-to-day logistics.

Why Choose Metalcraft

Our clients have access to the most diverse metal manufacturing facility in Colorado. We’re a one-stop-shop for machining, sheet metal fabrication, and metal stamping, and we run a tight ship. Stop by our establishment and see for yourself, we’d love to have you.