PRECISION SHEET METAL FABRICATION

Sheet metal projects go smoothly because we offer technologically-advanced sheet metal fabrication in Denver, strengthened by skilled labor and exceptional communication.

Old Meets New

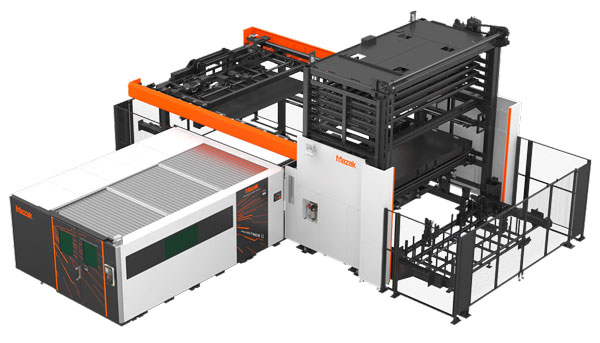

From the turret punch and press brake for bending to the cutting-edge fiber-optic laser with automation for lights-out operations, you receive a better, more cost-effective finished product through our tools and innovations.

We selected our automated laser system for its lightning-fast cutting speeds on a robust range of materials and thicknesses. Compared to the CO2 lasers of the past, fiber-optic lasers can cut sheets up to ten times faster and require less maintenance.

Modern fiber lasers use Nitrogen as the assist gas, and lots of it. We’ve invested in our own nitrogen generating system to eliminate downtime from missed deliveries of gas, as well as reduce our carbon footprint. Near-net cutting also reduces machining time in our CNC Machining department. What used to take hours we’ve reduced to mere minutes.

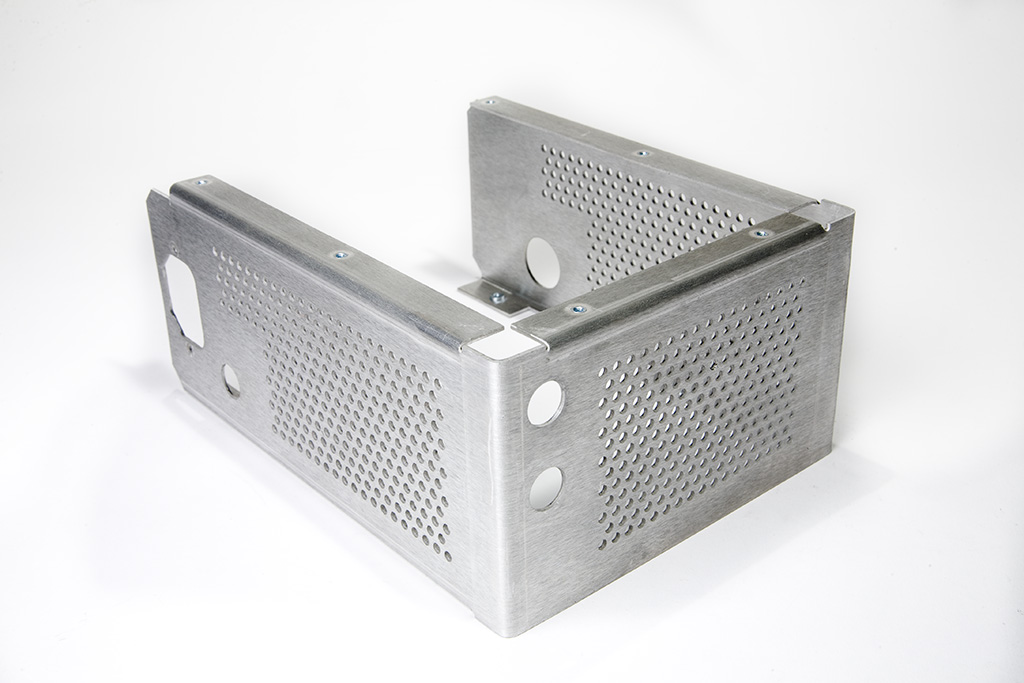

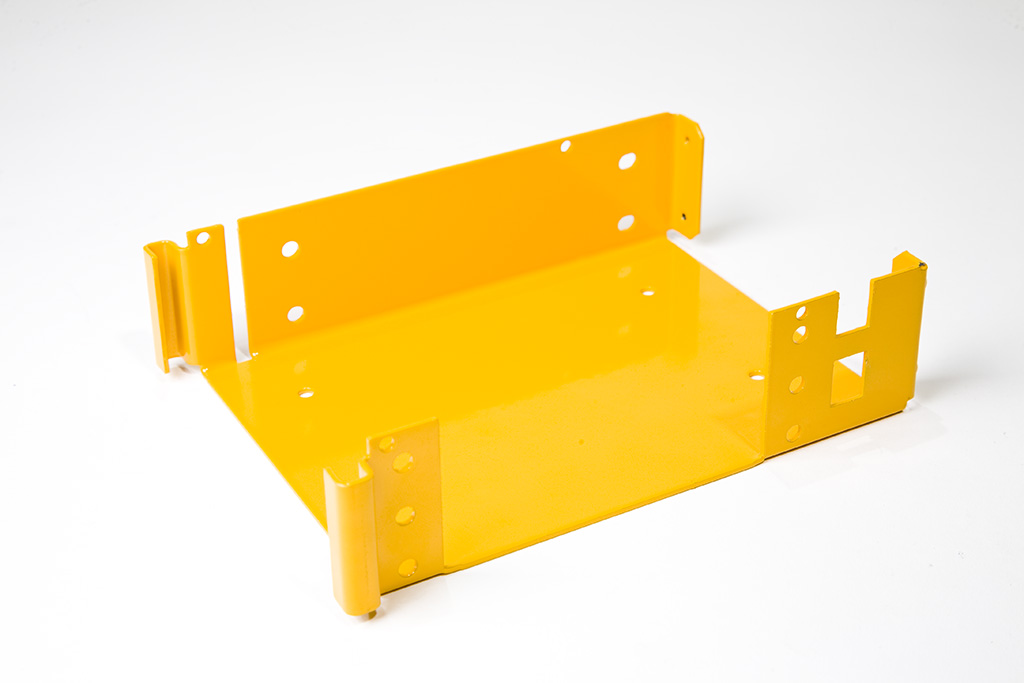

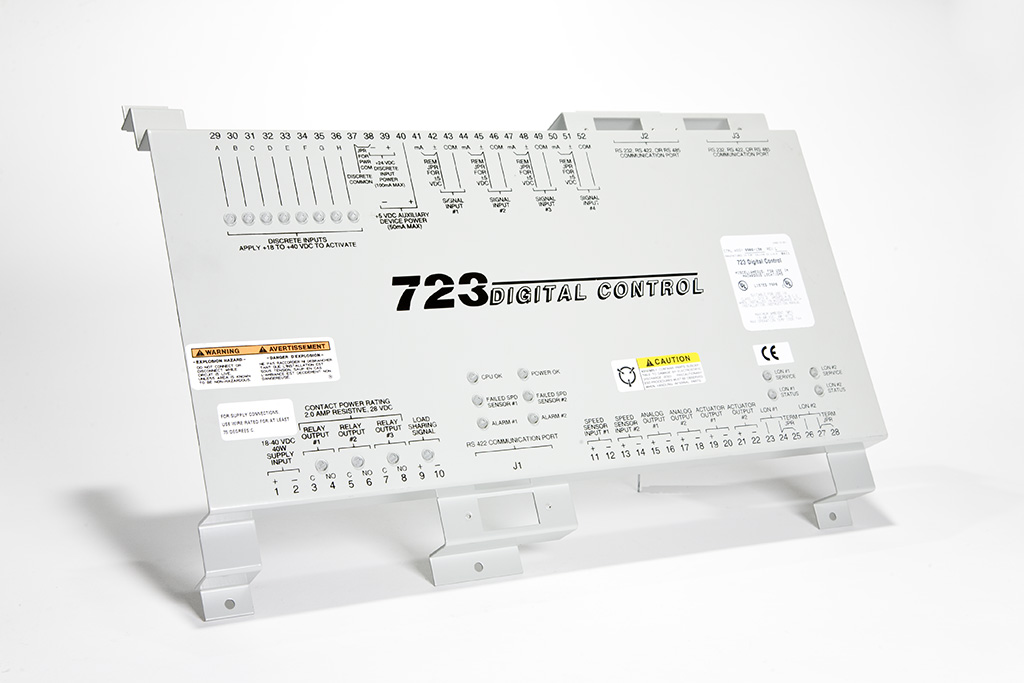

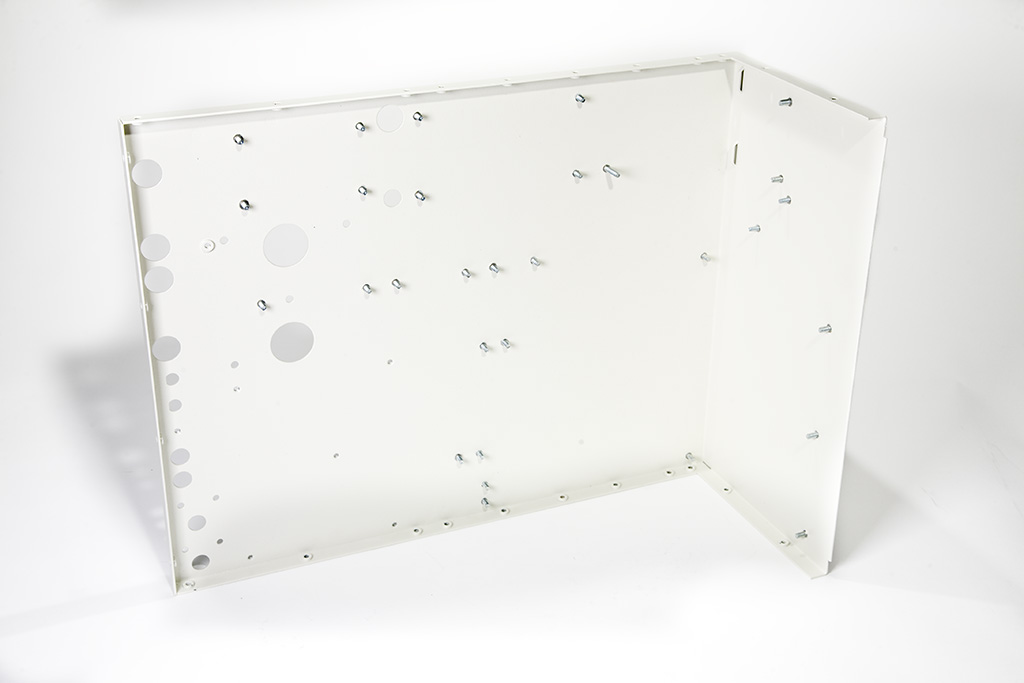

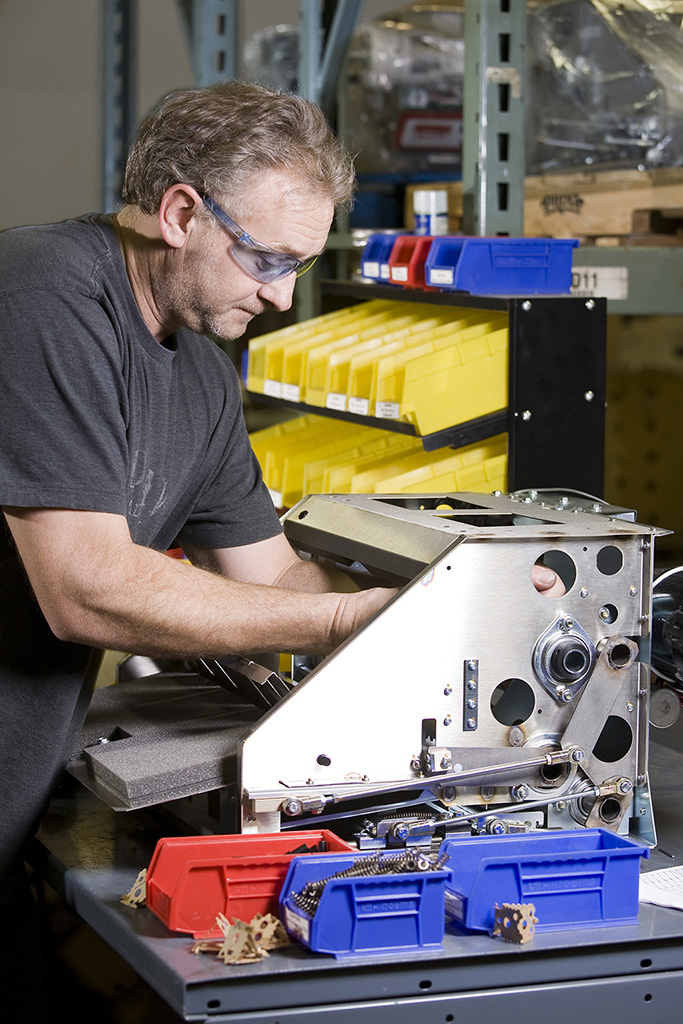

Parts We've Manufactured

Automation Means Accuracy, Reduced Costs, and On-Time Deliveries

We invested in our laser system because it helps our clients scale their businesses. The laser’s automation package streamlines operations while maintaining quality without the need for constant oversight, thus reducing labor costs. We call this “lights out” production— the machines can run even if we’re not here.

Hardware Insertion and Mechanical Assembly

The sheet metal process always requires some assembly, making our skilled employees essential to our success. Both our low- and high-volume clients trust us to get it right every time.

We are manufacturers with the hearts of engineers. Think of us as your collaborative partner who understands your specifications and is eager to see your product through from start to finish.

Distinguished Communication Standards

We know one of engineers’ chief complaints about vendors is a lack of transparency, so we keep you informed with frequent, open communication. Overpromising hurts you and us both, so our clients come to expect the truth without mincing words. Stop by our facility anytime and watch us make your parts. We’d love to have you take a tour.

We’re Responsive to Your Questions

If you have any questions during the sheet metal production process, just ask. We log every inquiry and do our best to respond within an hour. Then, our team works together to resolve your request.

Great Solutions, Together

You know your product and we want to learn from you.

We’re an extension of your business— your own personal manufacturing department. Through seven decades of experience, we’ve learned that tight collaboration from the beginning of the production process shortens execution time, increases quality, and streamlines repeatability. If you’d like, we’ll even help you with prototype and troubleshooting.

Eliminate multiple vendors with a single-source partner and solution. Together, we can devise great solutions.