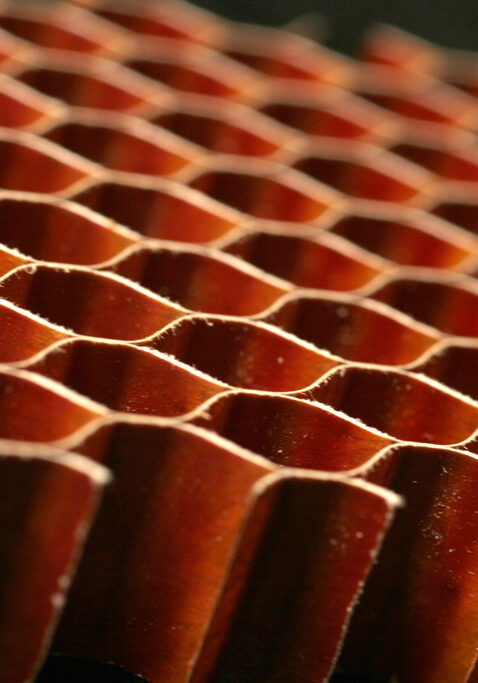

Metalcraft Honeycomb

Elevating Manufacturing Excellence

At Metalcraft Industries, we are redefining manufacturing excellence through our expertise in honeycomb technology. As leaders in the field, we harness the unique properties of honeycomb to craft products that push the boundaries of performance and innovation. Our commitment to advancing honeycomb applications enables us to deliver solutions that excel in aerospace, automotive, wind energy, and defense sectors.

By leveraging honeycomb’s exceptional strength-to-weight ratio and versatility, we produce components that not only meet the rigorous demands of high-performance environments but also enhance sustainability and efficiency across industries. Discover how Metalcraft Industries transforms honeycomb technology into superior, high-impact products that set new standards in manufacturing.

Contact us for More Information

Understanding how honeycomb, both the material and processing, is different from other modern materials.

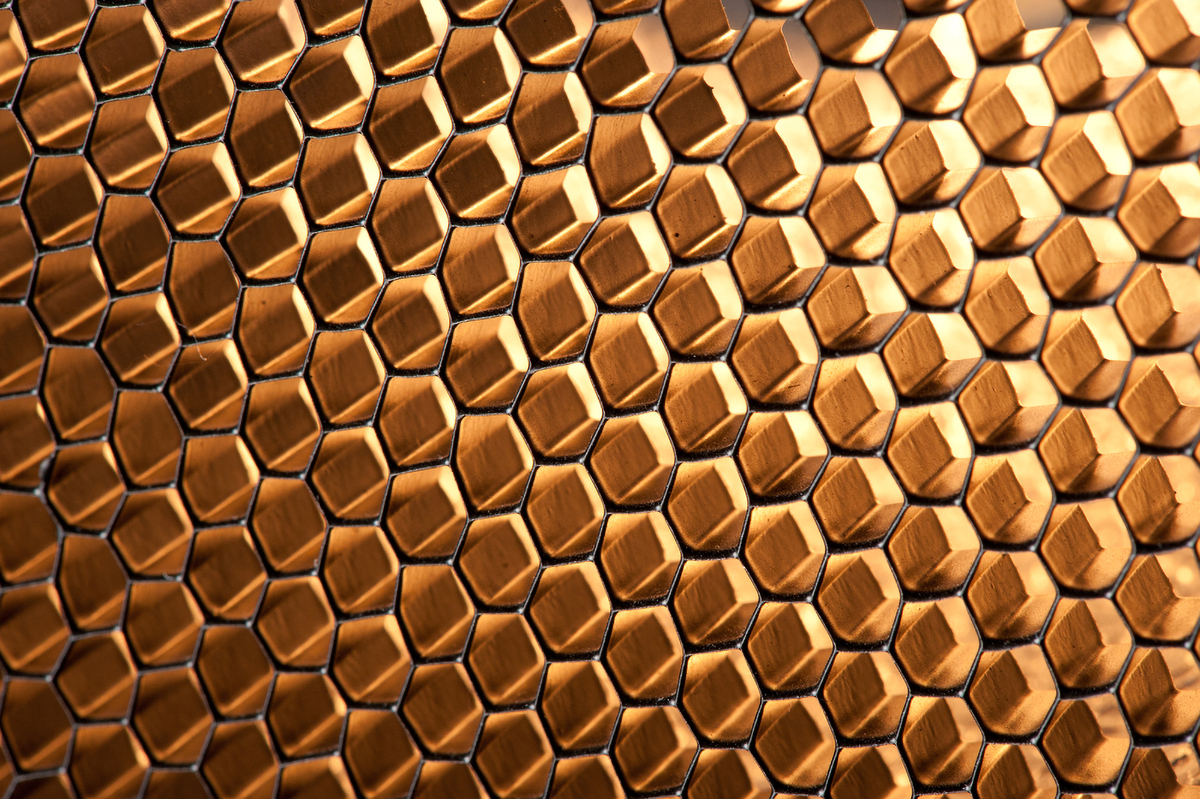

The honeycomb industry has numerous classifications of material types and uses but two of the most common (in aerospace and defense) are HRH honeycomb, which is aramid fiber constructed and HRP, which is fiberglass constructed. One (HRH) is high strength, lightweight and fire resistant, while the other (HRP) is High stiffness and higher fire-resistance with an added harsh environment capability. Whatever the specific type your project requires, we have the experience to make it happen and a plan to go forward.

Both the HRH and HRP varieties of this product are what is called phenolic honeycomb, which simply means that after the paper is laid up, for a particular type or size, like aramid fiber or glass fiber, the expanded block is cured in an oven. After it is cured it is dipped in a vat of phenolic resin and cured, successive times, until it meets the required specification for weight and strength for the application it is produced for.

Metalcraft’s history of innovation put us on a path to processing these exotic materials in the early millennium, for a market that needed reliable capabilities with our eagerness to innovate solutions. Honeycomb is unlike any other material and processing it requires entirely unique methodologies. Fixturing and machining must be approached completely opposite to how metal or plastic bars are typically managed, so a new way forward was engineered to accommodate these requirements.

Honeycomb’s processing requires entirely unique tooling and fixturing, which Metalcraft has pioneered and perfected over our years of experience with this material. It has tested both our forbearance and patience to develop methods to shape and measure it to geometric tolerances that challenge the most industry savvy facilities. Whatever the requirement, we have the capability. From small individual components to large panels or amorphous shaped aircraft filler structures, our team of specialists is equipped and prepared to efficiently fulfill your needs.

Here’s how we leverage honeycomb technology to enhance performance, efficiency, and sustainability:

Advanced Capabilities with Honeycomb Technology

Precision Engineering for Aerospace Applications: In the aerospace industry, every component must meet stringent performance and safety standards. Metalcraft Industries excels in creating high-precision honeycomb parts designed to withstand the demanding conditions of aerospace environments. Our capabilities include:

Lightweight Aircraft Panels: We manufacture honeycomb panels that combine strength with reduced weight, crucial for improving fuel efficiency and overall aircraft performance. Our panels are engineered to meet the specific load-bearing and aerodynamic requirements of various aircraft types.

Structural Components: We use honeycomb to create structural components that provide enhanced rigidity and durability. These components are essential for maintaining the integrity of aerospace structures under high-stress conditions.

Cutting-Edge Solutions for Wind Energy

Honeycomb technology plays a crucial role in the wind energy sector by improving the performance and efficiency of wind turbine blades. Metalcraft Industries specializes in:

Enhanced Wind Turbine Blades: We produce honeycomb core materials that are used in the construction of wind turbine blades. These materials offer an ideal balance of strength and lightness, allowing for larger and more efficient blades that capture more wind energy.

Structural Reinforcements: Our honeycomb solutions are also used to reinforce the structural elements of wind turbines, ensuring stability and longevity even in challenging environmental conditions.

Defense Applications

In defense applications, the need for strong yet lightweight materials is paramount. Metalcraft Industries leverages honeycomb technology to produce

Specialized Structural Components: We manufacture honeycomb panels that combine strength with reduced weight, crucial for improving fuel efficiency and overall aircraft performance. Our panels are engineered to meet the specific load-bearing and aerodynamic requirements of various aircraft types.

Why Metalcraft Industries?

Tailored Solutions for Your Needs: At Metalcraft Industries, we understand that each project has unique requirements. Our collaborative approach ensures that we deliver customized honeycomb solutions that meet your specific needs. We work closely with you to develop products that optimize performance, efficiency, and cost-effectiveness.

State-of-the-Art Manufacturing Techniques: Our advanced manufacturing capabilities enable us to achieve precise results and high-quality outputs. We employ cutting-edge technologies and methods to produce products using honeycomb pieces that adhere to the highest industry standards. Our facilities are equipped to handle complex projects and large-scale production with exceptional accuracy.

Commitment to Quality and Innovation: Quality is at the heart of our operations. We maintain rigorous quality assurance processes to ensure that every honeycomb product meets the highest standards of reliability and performance. Additionally, our focus on innovation drives us to continuously explore new technologies and methods to enhance our honeycomb solutions.

Sustainability and Efficiency: Metalcraft Industries is dedicated to sustainable manufacturing practices. Our honeycomb products contribute to environmental sustainability by reducing material waste, optimizing energy consumption, and extending the lifespan of components. We are committed to minimizing our environmental impact while delivering high-performance solutions.

Partner with Metalcraft Industries

Our advanced manufacturing capabilities enable us to achieve precise results and high-quality outputs. We employ cutting-edge technologies and methods to produce products using honeycomb pieces that adhere to the highest industry standards. Our facilities are equipped to handle complex projects and large-scale production with exceptional accuracy.

Contact us today to explore how our tailored honeycomb solutions can drive innovation and excellence in your manufacturing processes. With Metalcraft Industries as your partner, you can count on exceptional performance and unparalleled quality.