Having received feedback about our GD&T blog, I am writing material responding to requests to go over the basics. I can appreciate a reader’s desire for basics from the standpoint of people who learned the convention over the course of their job’s daily routines of making parts and seeing what works and sometimes what doesn’t.

Many people use GD&T but have little or no formal training in it. For those people, over the next few months, we will go through some basics from the ground up to fill in the possible gaps that some of you may have. Subjects covered will be:

- What is GD&T and how does it apply to engineering drawings and the world of manufacturing?

- Geometry: describing the world of shape and the arrangement of parts and features.

- Drawing fundamentals.

- The syntax of the language of GD&T.

- Datums

- Basic dimensions

- Feature control frames

- Characteristic symbols

- Modifiers

- Tolerance zones

This list should get us started. We’ll see how much interest it generates and expand into the use of the characteristic symbols and tolerance zones if more interest is there.

So let’s talk about what GD&T is.

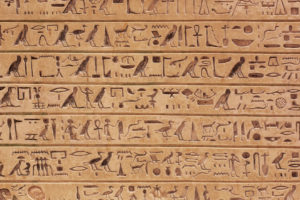

It’s a language, much like Spanish or English. It uses symbols, like our English symbolic alphabet, to represent an object, function or process. The need for a symbolic method of conveying ideas and function on engineering drawings can be easily understood if a person tries to imagine how they might describe a carburetor in words sufficient to allow a machinist to make one out of a block of aluminum. Pictures and symbols are worth a thousand words, and many more, so our engineering drawings give us access to tremendous caches of information in incredibly abbreviated forms, abbreviated but precise and detailed.

It’s a language, much like Spanish or English. It uses symbols, like our English symbolic alphabet, to represent an object, function or process. The need for a symbolic method of conveying ideas and function on engineering drawings can be easily understood if a person tries to imagine how they might describe a carburetor in words sufficient to allow a machinist to make one out of a block of aluminum. Pictures and symbols are worth a thousand words, and many more, so our engineering drawings give us access to tremendous caches of information in incredibly abbreviated forms, abbreviated but precise and detailed.

GD&T is many things.

It is a language that improves on the problems created by old coordinate and baseline tolerancing methods. It gives engineers the ability to precisely define geometry and the relationship of geometric features to a degree of complexity that was not possible before it was developed. It accomplishes this task with very few words and gives easy, precise control to both the geometric requirements of features and to the preciseness of the tolerances that will satisfy those requirements. GD&T gives engineers the ability to precisely say what they need and what will satisfy that need in the same sentence.

Now we’re going to look at some fundamental rules.

GD&T is a language but it needs to layout some fundamentals in order to assure that the playing field of the drawing space is approached the same from all sides. By that we need to understand that a drawing of a rectangle will be appreciated or understood in the same way by everyone who sees it. For instance, when we see a rectangle, you know, a 4 sided geometric figure with two sides measuring one length and two more sides measuring something other than the first two, we recognize it simply as a rectangle, right? Like the shape of a business card. We can picture the rectangle. But to do that we have already assumed some things. Our drawing shows four lines in the shape of our business card and we assume the inside corners of the rectangle are 90 degrees and that the lines meet at the outside corners, you know, like a business card. But if we weren’t allowed to assume that the lines meet at 90 degrees or that the lines actually did meet when we see them touching on a drawing then we would be in trouble. In GD&T drawing fundamentals cover these contingencies. Lines shown to meet at 90 degrees are said to be at 90 degrees without something that says otherwise. Lines shown parallel are said to be parallel. Lines that converge at a point on the drawing, like the 4 corners of our rectangle, are said to be at zero relationship to each other. These fundamentals are the underpinnings of our drawing system so that everyone that may need to understand the drawing will understand it in the same way. So to begin with, engineering drawings must make a complete definition of the items on it and all the items must have a proper tolerance. Those definitions and tolerances must have only one way to interpret them and having said that those things only apply at the drawing level they are on. This text only describes these fundamentals briefly and there is more here to embrace but this is a start. Next time we will begin the task of learning the components of our language and how its syntax, or the arrangement of its words, assembles to form meaningful statements. Our reader’s comments are always appreciated and welcome.