Chris Lindenberg studied GD&T for decades while working in manufacturing. He has taught and written about GD&T for nearly ten years.

He writes this GD&T blog for Metalcraft because he says, "I’ve spent the better part of my career arguing the finer points of GD&T. These discussions are ongoing for any company that uses GD&T to manage their part geometry and control their parts’ allowable deviations from design models and standards."

Definition of terms- Tolerance Zones

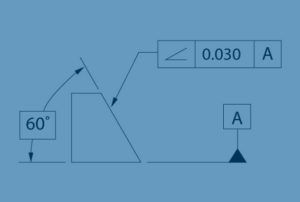

GD&T is a convention that gives the engineering world a tool that enables designed components to have both an unlimited variety of both geometric definition and tolerance. Consequently GD&T is about many things but it is ultimately about the disposition and appraisal of tolerance zones. This month our definition of terms will be about tolerance […]

Read MoreDefinition of Terms – Actual Local Size

Today our definition of terms will focus on “actual local size.” This term refers to a group of values that can be assessed and applied to any feature of size, values that establish the small and sometimes minute irregularities about a feature’s geometry. To understand what this means we first need to go back to […]

Read MoreDefinition of Terms-Datums and Datum Features

In the world of engineering and manufacturing, we say that GD&T gives us the ability to explicitly describe both nominal geometry and its allowable departure or tolerance from that nominal value. One side of the convention allows for the definition of the geometry and the other allows for the definition of tolerance. Accomplishing the definitions […]

Read MoreDefinition of Terms-Features and Features of Size

Today our featured GD&T term is “features,” which includes “features of size.” But before we jump into this we need to talk about a basic term or thing or maybe we’ll call it a concept, which is the term part. In GD&T a part needs to be thought of as an item, or two or […]

Read MoreDefinition of Terms- Basic Dimensions GD&T

In GD&T basic dimensions used to be a fairly simple thing to define. However, today, among other things, “Basic dimensions” are numbers on an engineering drawing that represent values of size in whatever the measurement system being used on the drawing is. Those values are used to describe the theoretically exact size, profile, orientation or […]

Read MoreDefinition of Terms-Concentricity

Today we’re going to look at the concentricity control. This control is used a lot in a variety of situations that involve coaxial relationships. The definition states that concentricity controls ‘all’ diametrically opposed elements of a figure of revolution. Breaking Down the Basics Let’s break that down and look at a few rules for […]

Read MoreDefinition of Terms-Parts and Features

Today I want to talk about a common definition for something we all talk about when the subject of GD&T comes up. I think it’s safe to say that the vast majority of people reading this series earn their livings on the floors of American factories. We design, machine, assemble, weld, measure, probe, form, punch, […]

Read MoreDefinition of Terms- Maximum Material Condition

With the previous topic, Rule #1, we discussed the need for a guiding principle to govern the need for geometry to follow rules that allow things to fit under all conditions, given that the proper engineering has been established for the condition being considered. That principal was stated as “size controls form.” In it the […]

Read MoreDefinition of Terms-Feature Control Frames

Today our featured GD&T term is “feature control frames.” We at Metalcraft decided some time ago to put together a glossary of sorts. It will be alphabetized in proper fashion but as various terms are added they will not be added in A to Z fashion, but more in order of importance, or more importantly, […]

Read More- « Previous

- 1

- 2

- 3

- Next »