Chris Lindenberg studied GD&T for decades while working in manufacturing. He has taught and written about GD&T for nearly ten years.

He writes this GD&T blog for Metalcraft because he says, "I’ve spent the better part of my career arguing the finer points of GD&T. These discussions are ongoing for any company that uses GD&T to manage their part geometry and control their parts’ allowable deviations from design models and standards."

Definition of Terms-Rule #1

Rule #1. In the world of engineering drawing there is an infinite amount of complexity to be detailed. All over the world there are parts and mechanisms that are dreamed up every day and for many of them there is a need for the assurance that a particular design will be flexible enough to work […]

Read MoreDefinition of terms- Actual Mating Envelope / Related and Unrelated.

Actual Mating Envelope – The Basics Actual mating envelope is a term that refers to a machined / manufactured part’s feature of size “as is” condition. To define what that means specifically, we need a specific individual part to talk about. The reason for that is when you have a part, or bunch of parts, […]

Read MoreThe Language of GD&T

In today’s installment I want to talk about the language of GD&T and perhaps a little about basic geometry and how shapes fuel our thoughts. Any language, to achieve communication, must somehow capture a physical method, accomplishable by our bodies, to change a thought or imagined image, into a physical presentation of some kind. Put […]

Read MoreGD&T Fundamentals

Having received feedback about our GD&T blog, I am writing material responding to requests to go over the basics. I can appreciate a reader’s desire for basics from the standpoint of people who learned the convention over the course of their job’s daily routines of making parts and seeing what works and sometimes what doesn’t. […]

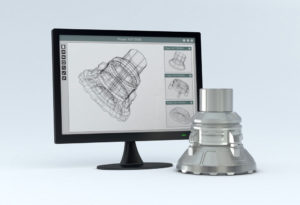

Read MorePartially Defined Drawings: Adapting to the World of CAD-Based, Geometry-Defined Working Drawings.

In this blog, we’ll discuss the tendency for many engineers to produce partially defined drawings (PDDs) that contain elements of GD&T but leave off the applicable basic dimensions. Not only that, but they fail to note most of the X-Y dimensions that define the geometry. When is it okay to leave information off drawings? But […]

Read MoreImplications of the GD&T System for Communicating Tolerances

The GD&T (Geometric Dimensioning & Tolerancing) protocol is rapidly becoming the standard for communicating engineering tolerances and allowable variation for product parts. It’s an elegant but not a simple system. Close to 50% of the GD&T drawings coming across my desk use the system incorrectly in whole or in part. This is not meant to […]

Read More- « Previous

- 1

- 2

- 3