Staying at the top of your business game means making smart strategic moves to meet the diverse needs of your clients in today’s rapidly evolving marketplace.

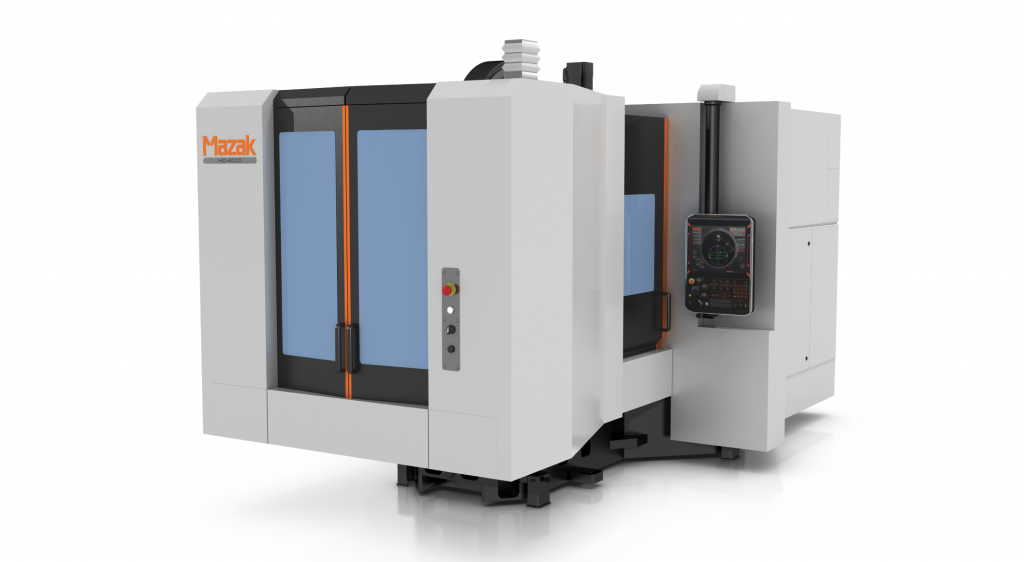

As our job orders increased in volume and complexity, we saw an opportunity to enhance productivity by upgrading our CNC machine. We went to Randy at Action Machinery in Englewood to explore the options and bought a new Mazak HC 5000 CNC system.

This innovative, big performing, small footprint model is a 500-millimeter horizontal machining center – fully automated – with two palette changers. It replaced our old vertical CNC unit, whose utilization rate was only 30%, meaning it wasn’t producing value 70% of the time.

Our production efficiency has improved dramatically with the HC 5000. It comes with an 84-tool carriage, twice the capacity of older machines, and two tables so that parts can be unloaded and loaded onto a tombstone while the machine is running other jobs. That means less set-up time per project, more capability, and a much higher spindle efficiency rate – now at 60%.

This investment in the future gives us the flexibility to grow with our customers as they bring more detailed concepts to us every day. Our President, Larry Caschette noted, “The Mazak CNC system is an important win-win for us. It ensures that we give our clients the best pricing possible while delivering the highest caliber products to their door, anywhere on the planet.”

Randy at Action Machinery who sells machinery to shops all over the country added, “With the addition of the HC 5000, Metalcraft has leveled the high tech playing field . . . they’re now competitive with any job shop anywhere.”

On behalf of our clients, we’ll continue living up to those words every day.