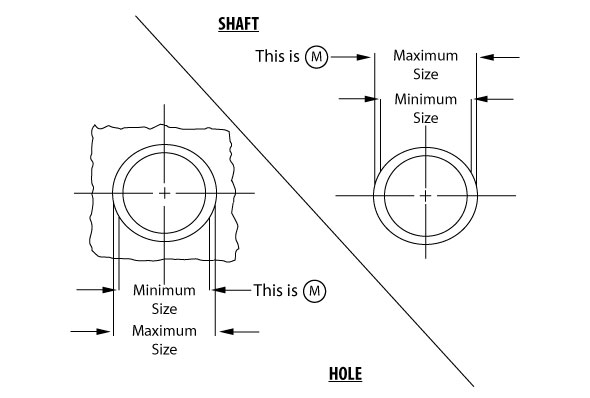

With the previous topic, Rule #1, we discussed the need for a guiding principle to govern the need for geometry to follow rules that allow things to fit under all conditions, given that the proper engineering has been established for the condition being considered. That principal was stated as “size controls form.” In it the statement says that “at maximum material condition” the geometry of all features of size must have perfect form.

What is Maximum Material Condition?

Maximum material condition, as it is stated or used in GD&T is a definition of limit not geometry. It is not the same thing as rule #1, it simply states the limit at which a feature of size achieves the MMC concept, which is, for any part that has in it or on it a feature of size, that feature of size is at maximum material condition when the part it is married to is at its heaviest, when it weighs the most. Put simply if a part has a hole in it that hole is a feature of size. The hole must have a tolerance associated to it by the fundamental rules of Y14.5. That part is heaviest; it weighs the most, when that hole is at the lowest possible end of its size tolerance. A part with a smaller hole in weighs more than the same part with a bigger hole in it. The hole is at MMC when it is at its smallest. The same principle is at work when a part has an external feature of size like a boss or protrusion. When the boss is at the largest end of its tolerance, it and the part it sticks out of are at their heaviest so external features of size are at MMC when they are at the highest end of their tolerance.

How Is MMC Utilized?

MMC is also used as a modifier in GD&T. Modifiers are a way engineers can add information to tolerance statements. When MMC is used as a modifier it adds a layer of complexity to the outcome of the manufactured part. The MMC modifier provides a choice for the maker to decide whether the values of some features, when chosen at a certain tolerance level (ultimately, tolerance choices, for all features and features of size in a given part, must be made,) can affect a value in the manufacturing cost of a part. These modifiers allow everyone in the manufacturing chain of events to make choices that lend the most quality, longevity, value and profit to the organizations that make those choices wisely.