Rule #1. In the world of engineering drawing there is an infinite amount of complexity to be detailed. All over the world there are parts and mechanisms that are dreamed up every day and for many of them there is a need for the assurance that a particular design will be flexible enough to work in either a specific duty as an assembled part or as a part that can be used over a wide category of common applications.

Commonality is Key

Whether a designed part is born in Mexico City or Vancouver Canada for it to perform its functions successfully it must have commonality with its intended uses or it will not be functional.

This means that a 14 mm bolt made in France must fit and assemble with a 14 mm nut made in Brazil. This task seems not too difficult but for these things to function, with all the possibilities of our physical world, there needs to be an overarching concept that guarantees that all the possibilities can and will sing from the same hymnal.

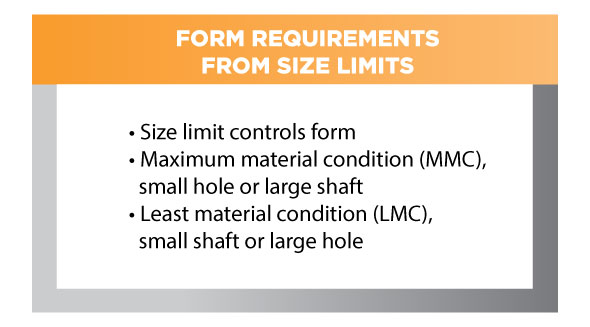

Size Controls Form

That concept is Rule #1. In its simplest iteration it means that “size controls form.” If we dig into what this means we see that no matter what geometry we might be analyzing there is an approach that says when something moves from one point in its tolerance to another, it must follow the concept that demands it to be more and more perfect in its form as it becomes closer to its maximum material state. That simply means for a part to change from one level of tolerance to another, in one direction it gets lighter and in another it gets heavier. Maximum material condition is when a part is at its heaviest and at that point Rule #1 states that it must have perfect form. Size controls form.

Perfect Form – Rule #1 in Action

To illustrate the value of this we can look at a simple metal shaft. It is designed to be 1.0” in diameter and it is 5” long. Those qualities, its diameter and length are given tolerance or we couldn’t make it. We couldn’t make it because we can’t make perfect things. Now back to the shaft. If it is made at .990” diameter and roughly straight then even when it is made in Barcelona it will fit in a 1.005” hole in a cast housing made in Atlanta. But!!! If it is 1.000” diameter and it is .005” NOT straight, not in perfect form, then it won’t go in that 1.005” hole. It will hang up because it does not follow the rule. Whether a geometry feature is internal or external, rule #1 will affect the possible assembly criteria of a design in the same way, anywhere. A design at its heaviest must have perfect form. Rule #1 assures form, fit and function.