In this blog, we’ll discuss the tendency for many engineers to produce partially defined drawings (PDDs) that contain elements of GD&T but leave off the applicable basic dimensions. Not only that, but they fail to note most of the X-Y dimensions that define the geometry.

CAD models don’t have tolerances and they don’t have notes

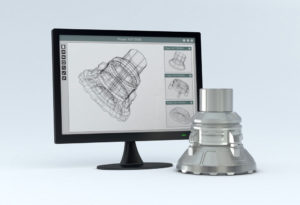

PDDs are becoming all too common in our shops and workplaces thanks to the prevalence of CAD-based engineering. Virtually everyone in the industry uses CAD (computer-aided design) to initiate, translate, or program the nearly infinite array of hardware we all produce. Computer models are now a way of life in our shops…but CAD models don’t have tolerances and they don’t have notes. Instead, of course, they communicate through 3D geometry.

The use of CAD has become so prevalent that the natural tendencies of the competitive marketplace are taking hold. Putting all that data in the CAD files would lead any designer or engineer to feel that using PDDs is acceptable and delivers the throughput they are being driven to achieve. But this happens at the expense of the downline manufacturers who rely on thorough drawing information.  Our world of drawings still relies on coordinate or baseline dimensioning techniques. GD&T is becoming more prevalent, and that’s good, all because of one key word: “unambiguous.” As engineering definitions become more unambiguous the process of producing parts that make automobiles roll and airplanes fly becomes less prone to quarrels and disagreements. But “quarrelsome” is how I would all too often describe the necessary exchange of information between designers and builders, because the current practice of part design and drawing interpretation creates disputes. “Quarrelsome” describes rejected parts and late schedules. “Quarrelsome” explains the need for GD&T. Humans communicate in words, while drawings are best when they have few words—a stated goal of GD&T. The ASME Y14.5 standard states that “dimensioning and tolerancing shall be complete so there is full understanding of the characteristics of each feature. Values may be expressed in an engineering drawing or in a CAD product dataset.” The fundamental rules that define engineering drawing practice are established and thorough. Anyone that needs to understand a feature on a drawing must have all the necessary definitions and tolerances.

Our world of drawings still relies on coordinate or baseline dimensioning techniques. GD&T is becoming more prevalent, and that’s good, all because of one key word: “unambiguous.” As engineering definitions become more unambiguous the process of producing parts that make automobiles roll and airplanes fly becomes less prone to quarrels and disagreements. But “quarrelsome” is how I would all too often describe the necessary exchange of information between designers and builders, because the current practice of part design and drawing interpretation creates disputes. “Quarrelsome” describes rejected parts and late schedules. “Quarrelsome” explains the need for GD&T. Humans communicate in words, while drawings are best when they have few words—a stated goal of GD&T. The ASME Y14.5 standard states that “dimensioning and tolerancing shall be complete so there is full understanding of the characteristics of each feature. Values may be expressed in an engineering drawing or in a CAD product dataset.” The fundamental rules that define engineering drawing practice are established and thorough. Anyone that needs to understand a feature on a drawing must have all the necessary definitions and tolerances.

When is it okay to leave information off drawings?

But the tendency toward PDDs and limited definition drawings is problematic. When is it okay to leave information off drawings? It’s happening—typically, when designers take these shortcuts it may work fine for them and even the company buying the products, but it leaves the Supply Chain out in the cold. The typical scenario is that definitional information is omitted but a note is added: Undimensioned features refer to 3D dataset,” followed by instructions to apply a profile control of perhaps .020” to those values. At a minimum, that kind of guidance is annoying to someone whose job it is to scour the model to see what’s hidden in hard to find places. Recently I quoted a drawing that had 13 feature control frames for a simple mounting plate. Along with a few hardware installation dimensions there were only two X-Y dimensions and no basic dimensions to go with those 13 frames. The part plate had more than 50 penetrations and the note that described how to find the excluded dimensions said “all of the dimensions taken from the 3D file are considered basic and shall be controlled by the tolerance indicated on the drawing.” That’s a PDD in the truest sense of the phrase, and it’s not uncommon to see something like this—even within the aerospace industry. Again, there are fundamental and detailed rules in place to define engineering drawing practices. But problems arise with ad hoc PDDs that happen to reflect someone’s personal view of what is sensible and sufficient or what a drafter thinks is compliant with ASME standards. If this is our approach as an industry, “quarrelsome” will continue to describe interactions between designers and builders, and this will drive out any hope for productive and efficient collaboration.