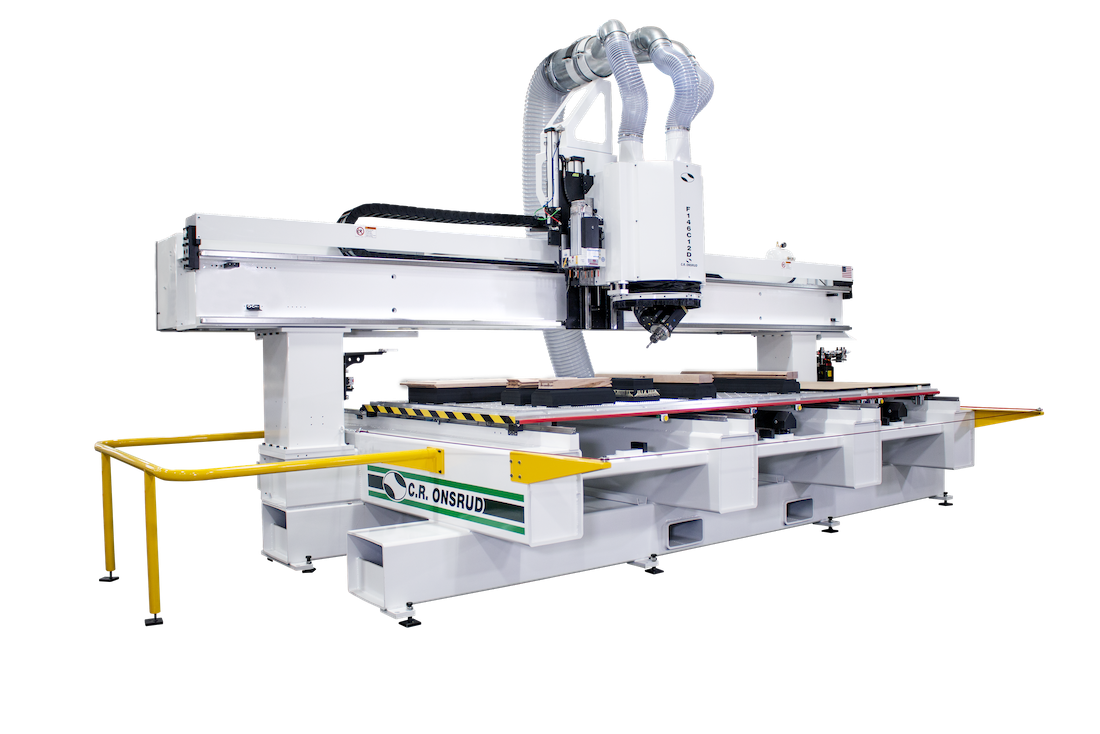

The 5-axis C-Series fabricates complex parts in large quantities and multiple sizes.

Denver-based Metalcraft, the only metalworking firm in Colorado with premium CNC machining, stamping, and sheet metal capabilities all under one roof, recently purchased C.R. Onsrud’s 5-axis C-Series to machine parts for its clientele, including a large company in the aerospace industry.

The 5-axis C-series’ Capabilities

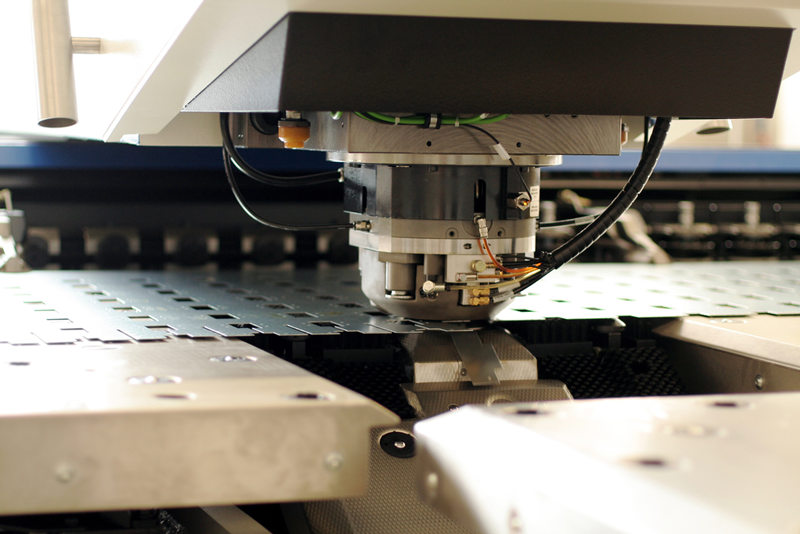

The 5-axis C-Series performs intricate 5-axis millwork within its large capacity, yet compact framework. It’s an exceptionally versatile machine, adept at handling an array of challenging applications. In a machining world that’s generally populated with machines that can work within a space of 6 to 10 cubic feet, the 5-axis C-Series is capable of a work envelope nearer to 80 cubic feet. Specifically, it’s ideal for cutting specialized composite and non-ferrous materials that would otherwise be difficult or impossible to machine on other conventional processing formats. One of Metalcraft’s engineers, Chris Lindenberger, provided an overview of the machine and its production capabilities.

Metalcraft Industries produces parts made from honeycomb cores. These parts are made from materials like paper and cardboard in low strength and low load applications, such as snowboards, packaging, or furniture, to high strength and stiffness materials like composite glass and plastic materials to produce extremely lightweight components for aircraft and defense hardware. “Honeycomb cores are fabricated in an array of many hexagon-shaped cells, assembled into a continuous structure. It is a material comprised of nylon paper and phenolic constructed in a very complex fashion. If I showed you a piece of it, it would look very much like it was removed from a beehive.”

Basically, this new machine takes pieces of material, like aluminum or composite honeycomb, and it turns them into specialized pieces per their customer’s designs and specifications. Lindenberger noted the specific model Metalcraft purchased is the F98C—which can be operated manually or automatically. “If you need to turn a piece of composite material, like honeycomb, into the shape of a void inside a fighter jet wing, we now have a superior machine tool to do so. It’s capable of producing very complicated parts in large quantities or large sizes. That’s what it’s made for.”

Lindenberger further elaborated on the 5-axis C-Series and its manufacturing output capabilities.

“Imagine if you had 100, $80-million aircraft, consisting of more than a million parts each, all machined on tools like we’re talking about. They all begin as larger pieces of material, that while being processed become their desired shape as small bits of material are machined away. This machine is designed to use specialized tools to remove those small bits. It will eventually produce the finished component in the shape described by the customer’s engineering drawing. It’s like Leonardo da Vinci taking a large piece of stone and chiseling away everything that’s not the statue of David.”

Dimensions, Uses, And Industries

The 5-axis C-Series, which Lindenberger estimates is approximately 16 feet tall, 14 feet wide, and weighs six tons, is often informally referred to as the “honeycomb machine.” It gained this nickname because it can seamlessly transform composite honeycomb and foam-core material panels into highly specialized aeronautic and defense components. He comments further:

“We call the machine a honeycomb machine because that is really why we bought it. We have machined these same honeycomb components on conventional machines for some time and this new machine will give us improved and additional approaches to producing these components. If we take all the honeycomb work that we do now, which is very complicated, and move it to this format, this machine will impact our job of producing a flawlessly quality product with increased speed and repetitiveness.”

The machine, also utilized in the automotive, furniture, packaging, logistics, medical device, and various other manufacturing industries, is extraordinarily precise and can simultaneously decrease downtime and increase uptime. Moreover, it diminishes the need for outsourcing, sharply enhances efficiency, and boosts productivity. For reference, thanks to the machine’s new, 5-axis large-format solution, Lindenberger predicts it could augment Metalcraft’s honeycomb machining capabilities by a large margin. But perhaps most important to the third-generation, family-owned manufacturing company that’s achieved a sterling reputation over three-quarters of a century, the 5-axis C-Series has multiple security features that make it remarkably safe to operate in the workplace. Lindenberger elaborates:

“This machine has system failsafe features that prevent operators from entering an envelope that would expose their limbs or body to any of the moving parts of the machine. And thank goodness, all modern automated machine tools must have these capabilities; they can’t be sold without them. It is a very safe machine that has guardrails, entry barriers, and safety interlocks to prevent accidental operations with bodies at risk. Its computer will shut down operations when programmed safety protocols are breached.”

Readying For Use

Recently, factory technicians from the vendor have been installing the 5-axis C-Series at Metalcraft’s plant. Subsequently, programmers and operators received specialized training to learn about the machine and its functionalities. Now that it has been installed, Metalcraft employees are preparing setups, programs, and tooling so it can achieve peak performance on its first project. Although the 5-axis C-Series is expensive, Lindenberger is confident that its benefits will more than compensate for its costliness:

“This machine can do many things and do them quickly and accurately. It’ll help free up so many things in the business and we’ll be able to focus on other work and innovate in other ways. Once everybody pitches in and makes it work, it should be a great addition to our company.”

If you need to produce very complicated parts in large quantities or large sizes, give us a call. With this new machine, we can speed your production process.