Today’s manufacturing world is full of challenges and opportunities. Our shop technicians change hats hour by hour to download programs and accomplish their setups. Among other tasks, they pull material, load tools, and edit and rewrite code. They measure, adjust, and change offsets. They fill out their in-process inspection data and submit the first pieces, and that’s all before lunch.

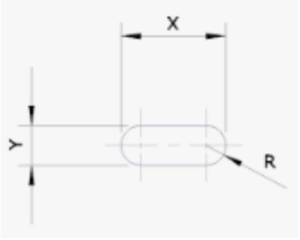

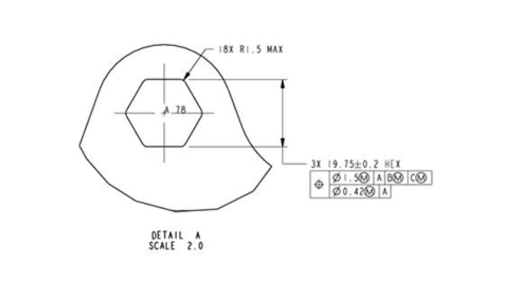

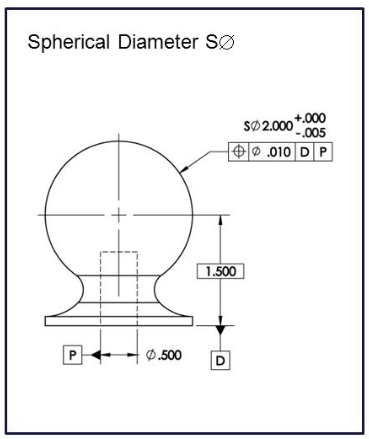

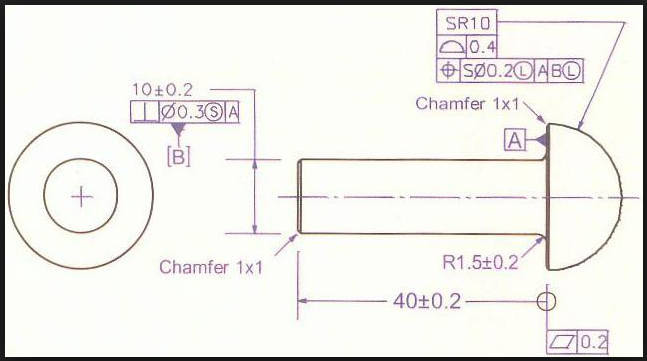

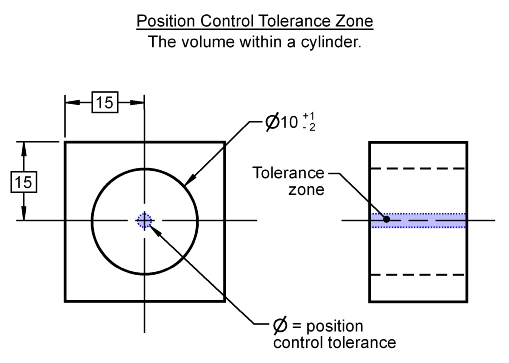

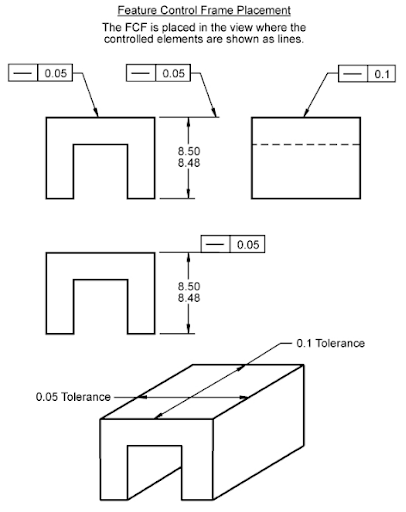

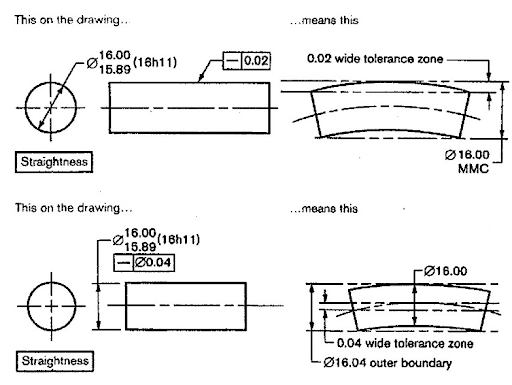

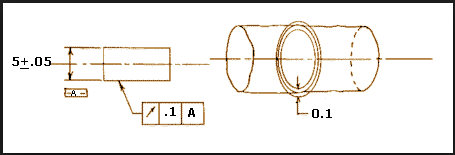

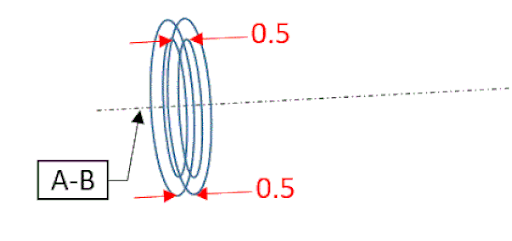

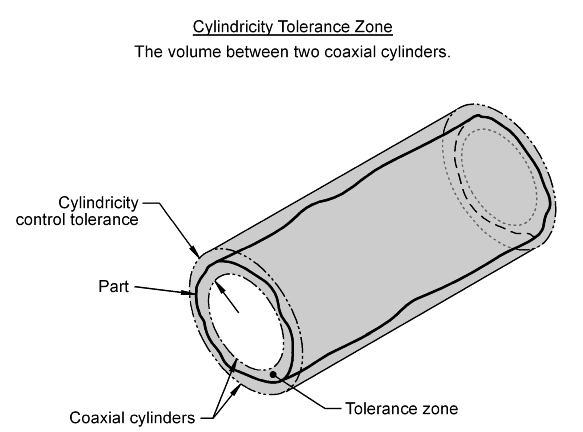

On top of the many things of which our technicians must remain knowledgeable is the practice and translation of geometric dimensioning and tolerancing (GD&T). GD&T is a vernacular all of its own. It’s used to specify and control the definition of hardware geometry coming from the world of ideas and concepts to bring those projects into the real world of shops with chips and scraps of metal on the floors and hot summer days and changing work shifts.

Learning GD&T is like Learning a New Language

GD&T is not something a person’s intuition guides them through. It’s a set of rules and procedures that demands you to do it right or don’t do it at all.

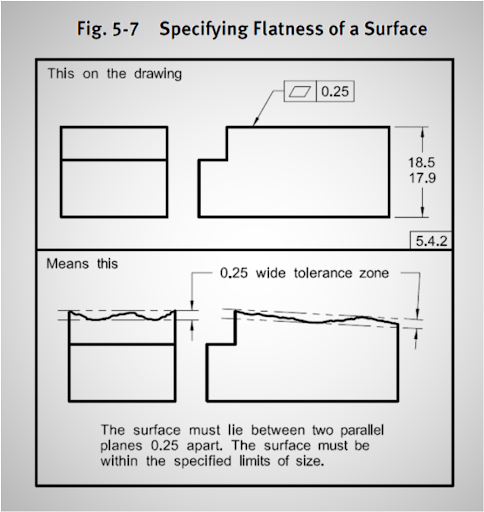

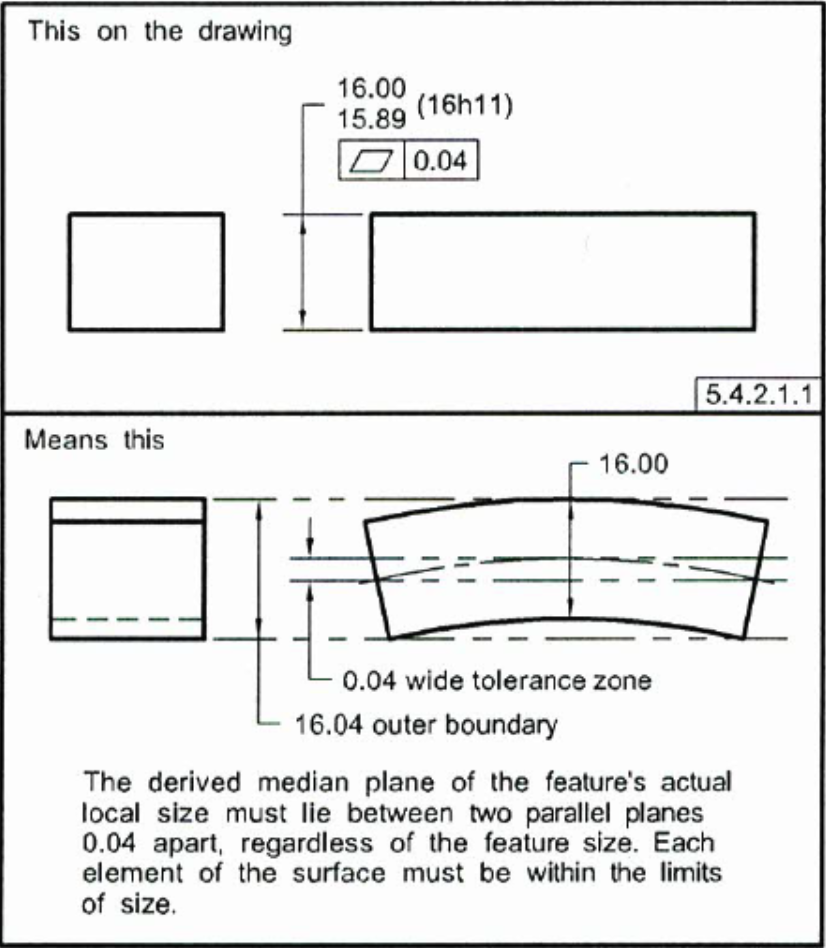

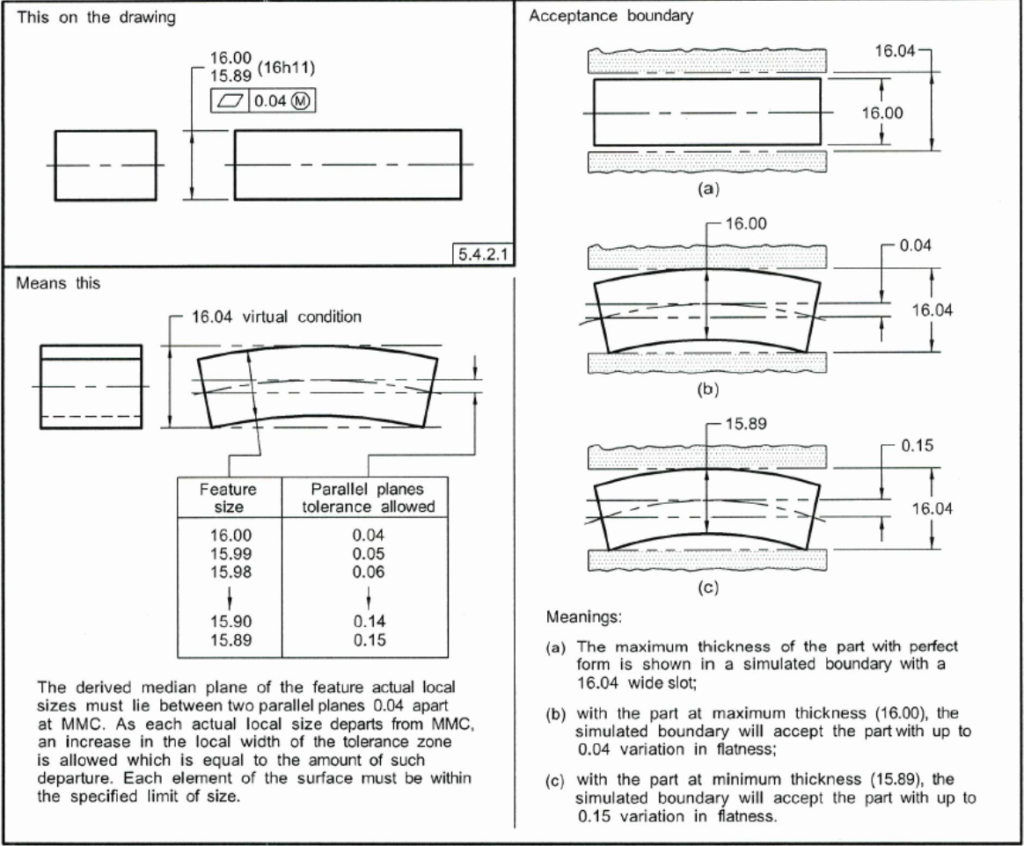

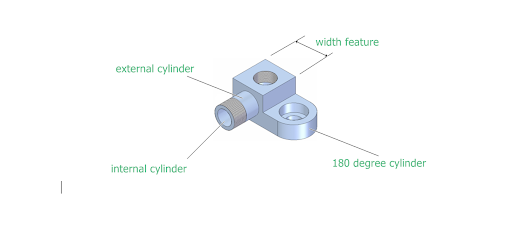

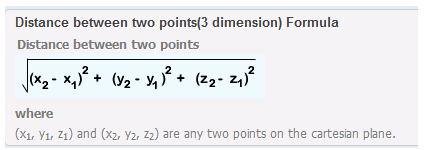

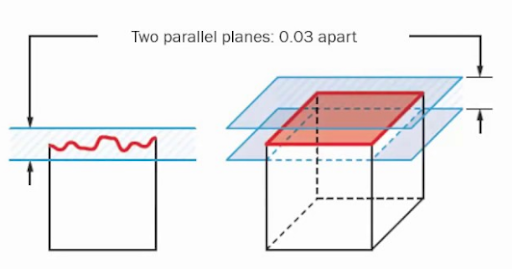

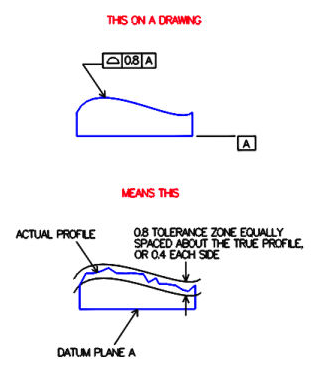

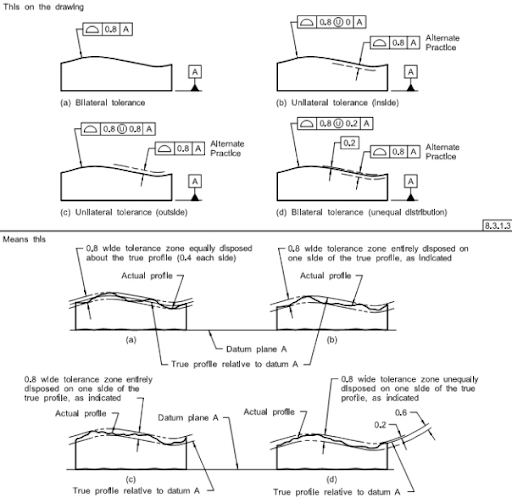

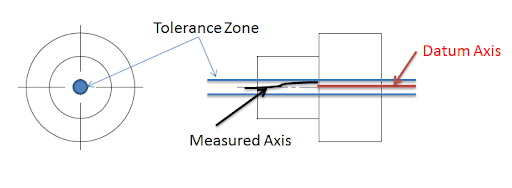

A person cannot learn simply how to read where a dimension begins and ends. GD&T is a complicated system of geometric symbology, a system that can describe, to any degree, the limits of form, fit, and function of literally an infinite set of physical circumstances. To that effect, once learned, GD&T becomes invaluable.

GD&T Requires Ongoing Education

We, as a company, try hard to “know what we don’t know,” but Metalcraft Industries exists in a world where GD&T often calls the shots. GD&T requires us to reassess drawing interpretations, before, during, and after parts are made on the shop floors.

Our shop personnel, engineers, and quality-control personnel participate in a company-wide training program to learn and practice the skills needed to read and interpret these controls and then how to apply it to their shop-floor practices.

Changes to GD&T Create Challenges

One of our biggest challenges is sorting out GD&T problems that make their way onto our estimating desks and sometimes onto our machines. We find that a good portion of the drawings that come through our door have GD&T issues and sometimes outright mistakes on them.

Engineers that use GD&T in their designs and shops that make the hardware all must adjust as it changes, so we can all profit by a closer study of its application.

Partner with Metalcraft

We’ve equipped our facility with the most diverse selection of machines in Colorado. Our engineer-minded machinists stay up to date with the changing industry, from GD&T to software, and beyond. Contact us for a quote, today.